Sherwood Ranger - Making Parts - 2

*This web site is NOT owned or managed by G-TLAC. G-TLAC is not responsible for the content unless explicitly stated. See Disclaimer.

12/9/10 - holes in .125 and .250 parts

1 hr - drilled the indicated lightening holes in the tailwheel mount plates. Rather than a pattern of 2 20's and a 14, I did a 19, 16, 13 (more or less, using an inch-size step drill, that's 3/4, 5/8, 1/2). I thought the intermediate step looked nicer. Also took the 1" holes in the wing root fittings up to 7/8, since that's the size of the larger step drill I currently have. I'll probably just leave them at that.

12/11/10 - patterns for .063 parts

1 hr - made patterns for .063 parts in cardboard. Got through 7 parts.

12/12/10 - patterns for .063 parts

0.5 hr - more patterns for .063 parts in cardboard. Got through 3 more parts.

0.5 hr - got through a few more .063 parts, and reviewed the list of .040 and .050 parts. A lot of these are just rectangles of the proper dimension, and made one more .050 cardboard pattern.

The cardboard patterns for the .063 parts that are not rectangles.

12/13/10 - order some metal

Ordered my preliminary list of nuts and bolts. I know it's not all of it, but it should be the majority. Also ordered a few 2'x2' squares of .040, .050, and .063. That may just about do it for flat metal parts. So from there it would need tubes, the firewall, a little 4130, and turned/machined parts (potentially from G-TLAC) to finish off the metal parts.

12/16/10 - received order

Spruce was having a free shipping deal, so no cost there, and at my EAA chapter's annual holiday dinner, the door prize I drew was a $50 Spruce gift card - no problem using that up either. Spruce chose to pack the 2'x2' metal in one package, the big bag of bolts (maybe 5 or 6 pounds worth) in a separate box. I unpacked the metal - very well done, no bends or scratches. I unpacked the bolts, but didn't go through them. Spruce accidentally charged the gift card amount to my credit card, but I called them and they reversed the charge right away.

12/17/10 - tool maintenance and .063 parts

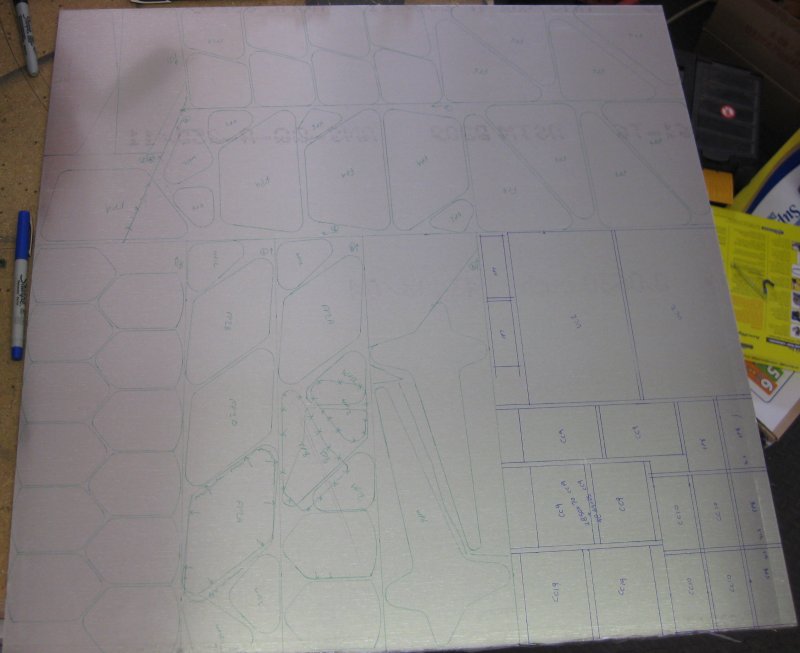

1 hr - traced around cardboard patterns onto the .063 sheet. Since these shapes are triangles, parallelograms, and other shapes without internal curves, I laid them out for pretty easy bandsaw cutting (no curved cuts). Also laid out the parts in "panels" a few inches wide, so I can rip off a panel, then cut the parts from it, rather than having to work each part out of the large sheet. Then laid in the simple rectangular parts, and without anything too hard to cut, it is possible to get all of the .063 parts into one 2'x2' square. Though I had ordered two of these, because my rougher estimate (considering only max dimension rectangles for each part, no nesting of triangles) ran a little beyond a single 2'x2'. Having an extra isn't a big problem, as I made the instrument panels for my Sonex of .063 and it worked well, so I was planning on using that here. Earlier in the day, I bought yet another bandsaw blade (I had bought one a few weeks ago that cuts fast, but much wider than the previous nearly-worn-out blade). I spent a little while getting the new blade installed. Since I went to a woodworking shop, they also had replacement blade guide blocks, so I changed those out as well.

All of the .063 parts laid out on the 2'x2' sheet. Actually, two small triangular gusset plates are not on here because I found a small piece of .063 in the workshop (on the order of 2" x 2" - really small), but they would fit in the area around the long, odd-shaped aileron brackets.

12/18/10 - .063 parts

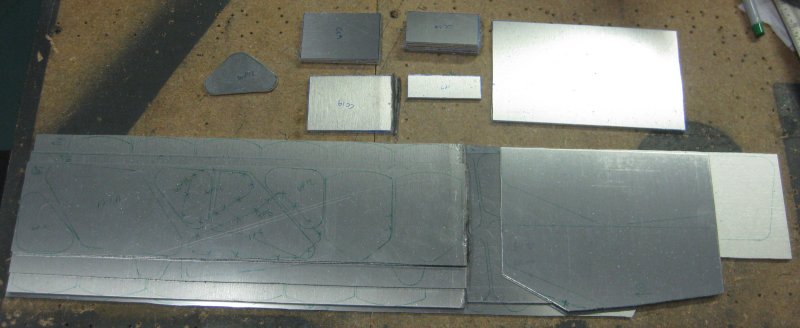

1/2 hr - ripped the 2'x2' of .063 down into smaller sections. Also cutout all of the simple rectangular parts from the sheet. The new bandsaw blade is better than the HD one, but not quite as smooth as the old worn-out one. But this should work.

The 2'x2' sheet ripped down to smaller rectangles, and the rectangular parts cut from the sheet.

12/18/10 - .063 parts

1/2 hr - started sanding and polishing the edges of the .063 parts. Got through a few of the simple rectangular parts, plus two of the little rounded-triangular gusset plates.

12/19/10 - .063 parts

1/2 hr - cut apart a couple of the small strips into individual parts. Using one side of each part as a guide to the cut, now just have to remove the excess material from the remaining sides of each part.

12/19/10 - .063 parts

1/2 hr - belt sanded and Scotchbrite-wheeled a few more of the .063 parts. Got through 8 small rectangles and two of the larger odd-shaped pieces.

12/20/10 - .125 parts

1/2 hr - belt sanded and Scotchbrite-wheeled a few more of the .125 parts, maybe 5 more.

Click to join sherwoodbuilders