Sonex* Ailerons

*This web site is NOT owned or managed by Sonex, Ltd.. Sonex, Ltd. is not responsible for the content unless explicitly stated. See Disclaimer.

Aileron construction is very similar to flaps & rudder, so this page is to show differences.

Setup for pouring aileron counterweights. Used small torch (for sweating pipe) to melt 4# dive weights. Mold made of particle board. It scorched, but the weights came out very close to the right size. Dive weight on left by screwdriver. Scorched mold in center, first cast counterweight above. 8/14/99 (posted 11/21/99)

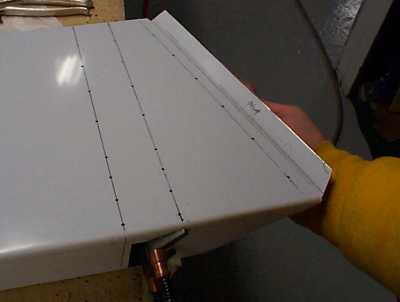

Balancing aileron. Used 2x4's on each end of hinge pin. No adjustment required. 1/21/00

Balancing aileron. 1/21/00

Balancing aileron. 1/21/00

After doing the first aileron 8/99 and quickly proceeding to make an incorrect cut on aileron skin #2, I'm finally getting back to the 2nd aileron. This shows how I did the end rib - put the bottom 2 flange bends on it, then held it against the aileron to mark the 3rd bend. Line shows where flat pattern would have put the bend, leaving the end rib too large. 1/22/00

Finally have a pair of ailerons. Found that when drilling the weight, just go direct to the 3/16" final size. It will stick 4 or 5 times per hole, but won't snap off in the hole. Lead is so soft I found it much easier to just go for the final size rather than step drilling through several different size holes. 2/3/00